Kamber

Kamber Software

Automated design of expanded web beams

Expanded Web Beams

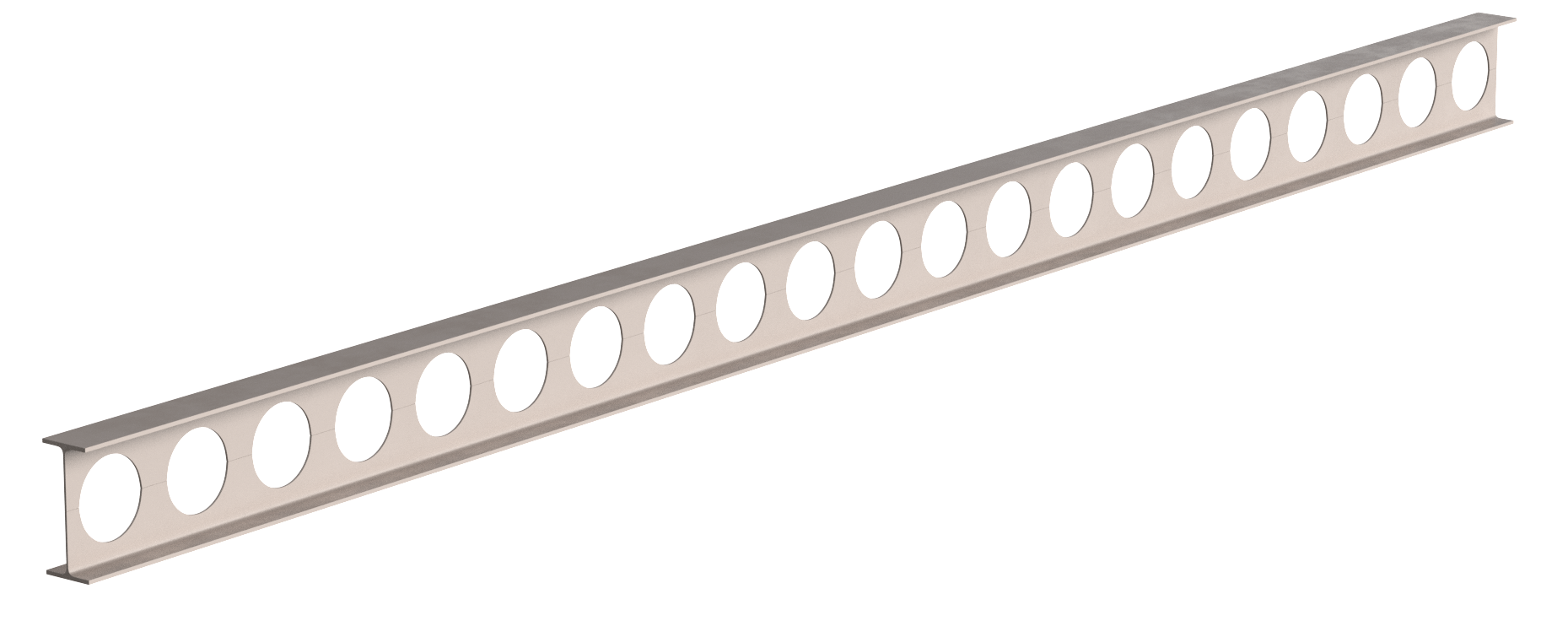

Expanded Web Beams (EWB) are the ultimate form of the humble I-beam. While I-beams are the sharp blade of bending members like joists and girders the transformation to EWB shows that I-beams are actually a multi-tool in disguise.

It's an old and clever idea that's seen a resurgence in recent years due to EWBs being efficient for steel weight and for having building construction's favorite feature — holes.

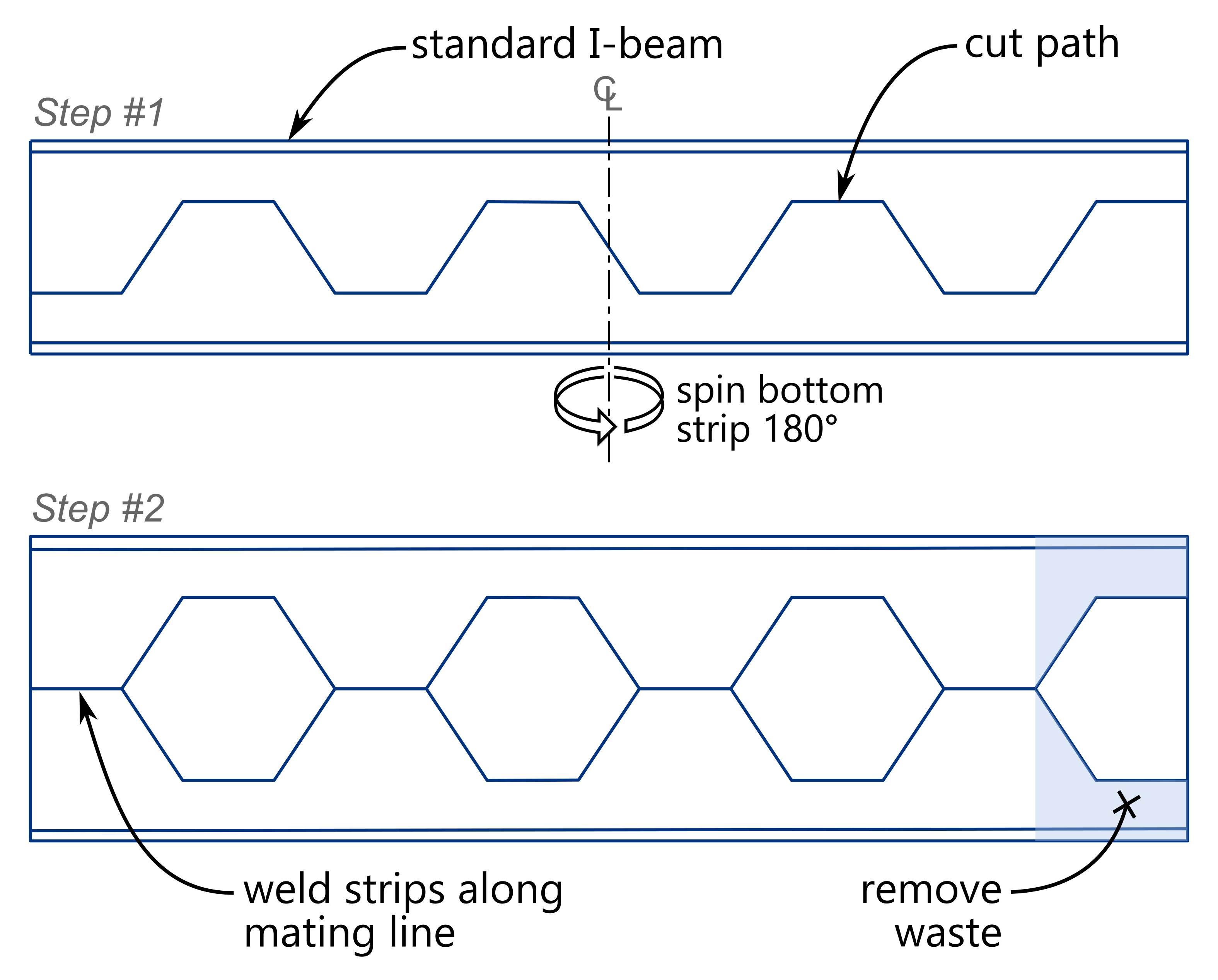

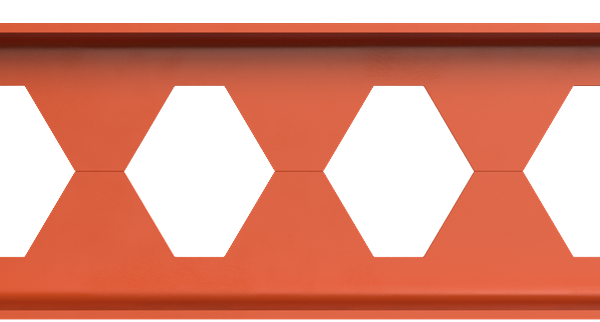

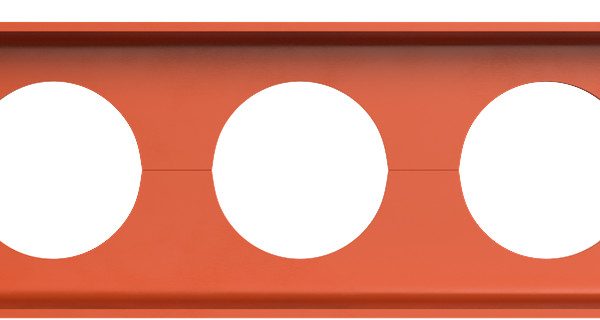

The hole patterns in EWBs come in three flavors:

| Castellated | hexagonal web openings |  |

| Cellular | circular web openings |  |

| Sinusoidal | rounded hexagonal web openings |  |

Implications & Aesthetics

There's no denying that EWBs are more interesting and aesthetically pleasing than standard I-beams. Where plain I-beams are boring and forgettable EWBs are captivating and memorable. Patterns can be adjusted to suit the architect or owner's preferences, too, though a compromise between pattern manipulation and cost (source beam sizing) is sometimes required.

Castellated and sinusoidal patterns are the most affordable due to requiring only one cutting pass per beam. Cellular beams require two cutting passes to attain circular openings.

EWBs are naturally more suited to uniform loads than to concentrated loads. While concentrated loads such as RTUs and similar can be accomodated, they often require light subframes between EWBs so the concentrated forces can be routed to the posts, or the full-height sections between web openings.

Advanced Applications & Add-ons

Composite Steel-Concrete

EWBs are most commonly used as roof and floor beams to directly support steel or wood deck, SIPs, wood planking, or similar. Higher load capacity, greater stiffness, and longer spans are achievable, however, if using EWBs compositely by rigidly attaching them to a cast-in-place concrete slab laying on top of the EWBs. Composite action is attained by welding studs to the top flange of the EWBs, same as for composite beam-slab systems using plain I-beams.

Pattern Alignment

When many EWBs are to be installed alongside one another in a common bay then the web openings can be aligned. The best and most cost-efficient option for aligning web openings is to have all EWBs be the exact same length. We can provide varying patterns of openings throughout a bay when the EWBs will be varied in length, but these designs are more costly both computationally and for the fabricator. Stepped variations in beam length and minor length variations are more affordable than continuously varying beam lengths and/or major changes in length.

Multiple Source Beams

Large projects can sometimes benefit from using different source beams, where the top and bottom strip of each EWB are taken from two different source beams. This unique approach is most beneficial when used for composite roof and floor systems.

return homeContact

Please get in touch and tell us what we can create together.

We love making metal happen.

- © Kamber Software

- Design: HTML5 UP